How to produce Ruthenium Iridium coated Titanium Anodes?

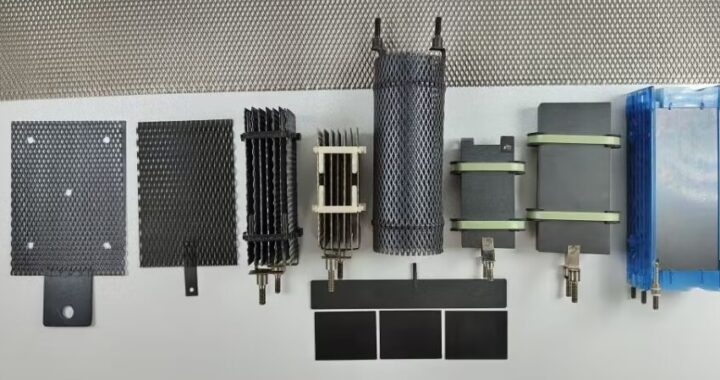

Titanium anodes are widely used in electroplating and other industrial processes. However, they can face corrosion and other issues, which can affect their performance and lifespan. To overcome these issues, many industries now use Ruthenium Iridium coated Titanium Anodes. These anodes have excellent corrosion resistance and can last longer than traditional anodes. Here’s how to produce Ruthenium Iridium coated Titanium Anodes.

Step 1: Cleaning the Titanium Anodes

The first step is to clean the titanium anodes. This removes any dirt, oil, or other impurities that may affect the coating process. You can use a chemical cleaning solution or use mechanical cleaning methods like abrasive blasting or ultrasonic cleaning.

Step 2: Coating Preparation

In this step, the anodes are prepared for the coating process. They are first rinsed with distilled water to remove any remaining cleaning agents. Next, they are immersed in an acid solution to remove any oxide layers present on the surface. This allows for better adhesion of the coating.

Step 3: Coating Application

The coating is applied by electroplating. In this process, the anodes are connected to a power supply and immersed in a solution containing Ruthenium and Iridium ions. A current is passed through the solution, which causes the metal ions to deposit on the surface of the anodes. The thickness of the coating can be controlled by adjusting the current strength and duration of the process.

Step 4: Post-Coating Treatment

After the coating process is complete, the anodes are rinsed with distilled water to remove any residue or impurities. They are then dried and heated in a furnace to a temperature of around 400 degrees Celsius. This process is known as annealing and helps to improve the adhesion of the coating to the surface of the anodes.

Step 5: Quality Control

The final step is to ensure that the coating meets the required specifications and is of high quality. This involves testing the anodes for thickness, adhesion strength, and overall performance. The anodes that pass the quality control test are stored and shipped to customers.

In conclusion, Ruthenium Iridium coated Titanium Anodes are popular in many industries due to their excellent corrosion resistance and high durability. By following the above production process, companies can produce high-quality anodes that meet the needs of their customers.